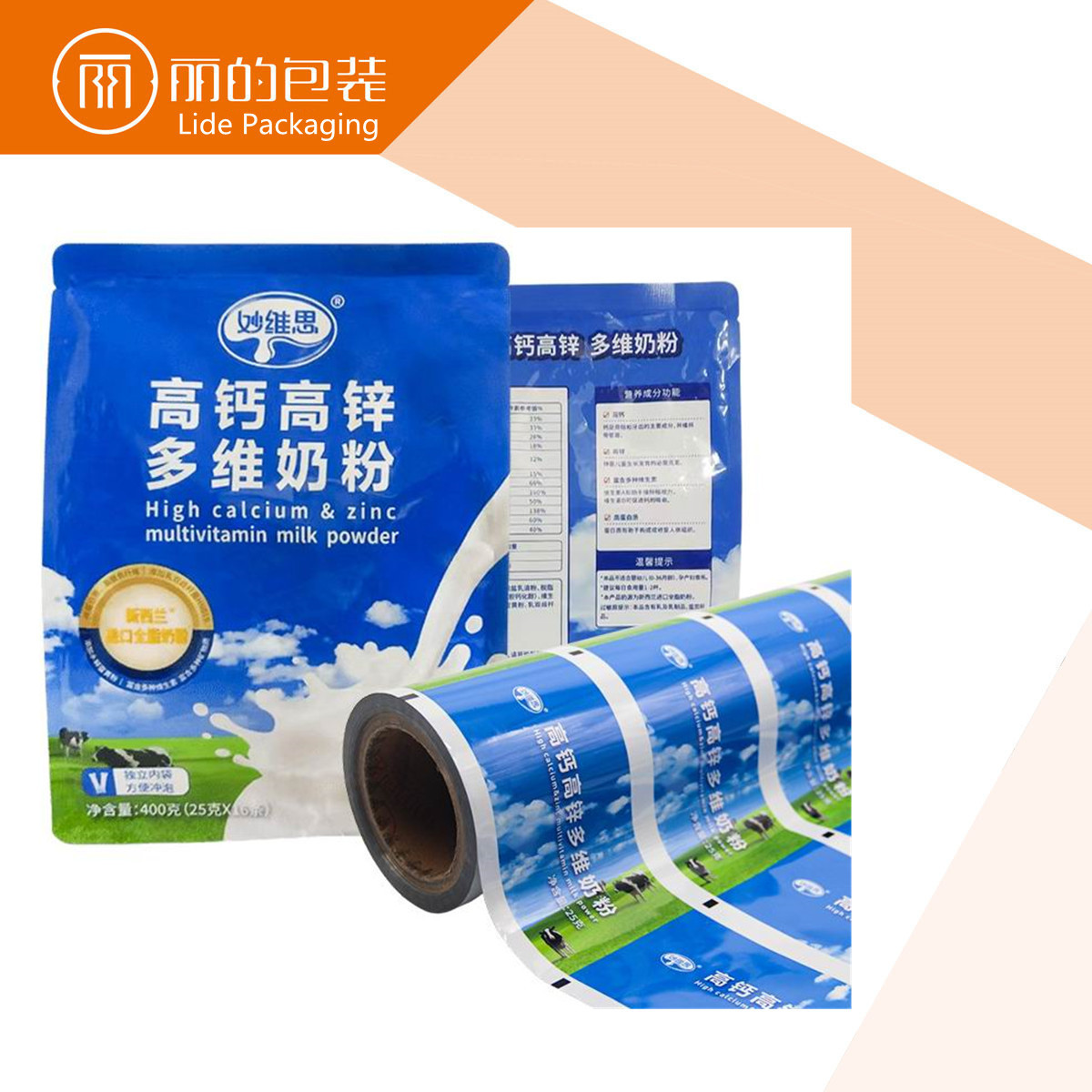

Recommended products

With mature printing technology, all kinds of production equipment and technology, excellent quality inspection equipment and personnel, styles, specifications, according to customer requirements to sample processing. The company has newly introduced many equipment, including penetrator, tensile testing machine sealing tester, heat sealing tester, impact tester, gas chromatograph and other excellent machines.

View MoreThe company has successively passed QS quality and safety certification, ISO9001 quality system certification, BRC international standard certification, Disney official certification, etc. The company adheres to a scientific and rigorous management system, continuously improves product quality and service level, and has won the trust and praise of many customers.

View MoreSINCE 1997

LIDE PACKAGING

About Us

People-oriented, customer first, quality first.

Since its establishment in 1997, LIDE Packaging (Guangdong) Co., Ltd. has always adhered to the basic concept that quality is the foundation of the enterprise, and will be rigorous and serious self-requirements throughout every production detail. We uphold the inheritance and development of craftsmanship, combine technology with modern technology, and meet the needs of different customers with increasingly refined production, technology and design and development capabilities. We gather professional and technical personnel in the industry, relying on strong technical strength, rich industry experience and excellent production team, continue to expand business areas, use strength and professional knowledge to create better products and services, and ensure that every product is strictly controlled, Interpret the beauty of packaging from a new perspective. Through continuous technical upgrading and iteration, your needs can be high quality met and escort the long-term development of the enterprise!

Large production line and management team

large production base

To undertake all kinds of large orders

Daily production

The strength of the factory let you rest assured

Annual output value of the company

Customer service above all

Industry deep plowing personnel

One-stop custom service

One stop customization

OMD/OEM factory, all according to your demand production

Products are willing to use materials

Focusing on customization

The same paragraph with the quality of the product, the material is good, the price is cost-effective.

Certificate variety, peace of mind quality

High quality

Years of experience in foreign trade, we have all kinds of qualifications, please rest assured cooperation.

Focus on customization, fast delivery

Focusing on customization

Support expedited production, delivery guarantee, complete warehousing and logistics

Workshops

Beiren high-speed laminating machine

Beiren High Speed Printing Machine

high speed bag making machine

high speed slitting machine

High-speed quality inspection machine

Excellent testing equipment

Customized types

Support a variety of bag type customization

Automatic packaging roll film

Cup cover film

Easy tear film

Heat Shrinkable Film/Label

Three side seal bag

Back seal bag

Organ back seal bag

Medium seal organ bag

Medium seal bag

Self-supporting zipper bag

Self-standing bag

K-Bag

Our Partners

Our Exhibition

Information

LIDE

QQ:735974933

Address: West side of Jiaoshan Road, Guolong 3 Village, Anbu Town, Chaoan District, Chaozhou City, Guangdong Province , China